Role Of Plastics In Construction Industry

For centuries, the construction industry has been using wood, glass, and metal materials for building homes. However, from the beginning of the 1950s, plastics came into picture and have been giving so many benefits to the construction industry. These days, injection mould manufacturers in India use various plastic types in construction, starting from flooring to roofing. Injection mold manufacturers also use plastic as insulation, walls and pipes, and are also used to manufacture doors and windows. Many heavy equipment and tools used in the construction industry have many plastic components.

Benefits Of Plastic Injection Molding To Construction Industry

Here are the major benefits of using plastic injection molding in the construction industry.

Cost

When you decide to use plastic injection molded parts, you can save a good amount on the expected budget. Copper tubing is usually the traditional choice; however, PVC tubing might cost only a percentage. If the project is huge, the customer can save more money. Mostly, when you opt for materials like copper, it can cost you more money in the transportation itself because of the weight of the material. However, when it comes to plastic injection molded materials, transportation costs can be saved as the molded materials are lightweight.

Weight

Projects do have weight limitations. When you bring is small parts, but in a huge volume, it can increase the weight and affect the project’s budget adversely. Substituting plastic for heavier materials can help in such weight restrictions. If you can swap copper tubing for PVC, wooden sheets for PEX, or steel braces for plastic, you can very well save a huge amount in the projected budget.

Durability

When deciding to select plastic, one should consider the resistance to the elements. One of the major benefits of using plastic is that they are resistant to nature and other elements. For example, corrosion and rust cannot affect PEX. Heat and humidity can affect wooden shingles wherein, good plastics can remain the same even if there is any change in the environment. Many materials leaves residue; however, plastic is one such material that is stain-resistant and quite easy to clean. Plastic also requires less maintenance when compared to other materials such as metal or wood.

Repair

Fixing a plastic part and replacing the same is quite an easy task. Modifying a plastic part is so easier than doing the same to a metal part. Plastic repairs can be done with the help of some glue or by cutting off the damaged area or even replacing it. When you plan to do modifications on a metal part, you might first have to find a person who can deal with the issue, and there are chances that you have to remove the entire metal part and buy a new one. By fixing the damaged part of the metal, there are chances that you might spend more money which equals the cost of a new metal part. Opting for a lightweight plastic part does not need any maintenance, and it can run for a long time.

Recycling

One of the biggest advantages of using plastic parts in the construction is that they can be re-purposed and re-molded. This can save a huge amount for both the client and the builder and all those who are vocal about using eco-frindly materials. Even if a building is deconstructed or demolished, the plastic parts can be used for many other purposes, i.e., recycling. Worldwide, construction companies are making an effort to help the environment from pollution, and with plastic injection molded parts, they are successful in doing that.

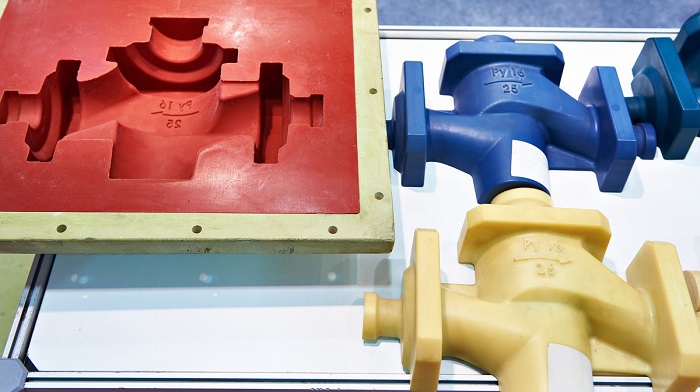

Presentation

Molded plastic parts come in various colors and textures. These parts can be modified on-site and become part of the finished product. Changing the color of the plastic parts is much easier than changing the color of a wooden product or a metal product. Because of their smooth appearances and solid colors plastic injection molded parts have been a popular choice among many construction industry manufacturers.

Plastic injection molded parts are helping the commercial construction and the general contractors. Due to their lightweight property, versatility, and flexibility, contractors often select them, whether it is a big or small project. Know More

Leave a Reply